In recent years, high-end customization slowly into the lives of the public at the same time, the furniture "high definition" also represents a high-level requirements for people's living environment, now has become an unstoppable trend.

So furniture companies to meet customer demand for customized furniture, how to improve the efficiency of processing and manufacturing, cost savings? High-quality edging means not only the need for high-quality panels and edging materials, but also the need for a high-quality edging machine in order to complete the "high definition" edging needs.

Edge Banding Machine Process

Edge banding machine is to complete the traditional manual operation process with highly automated machinery. It includes many processes such as conveying, gluing, cutting, front and back flush, up and down trimming, up and down finishing, up and down scraping, polishing and so on in the straight-sided shaped edge sealing.

INVT Solution

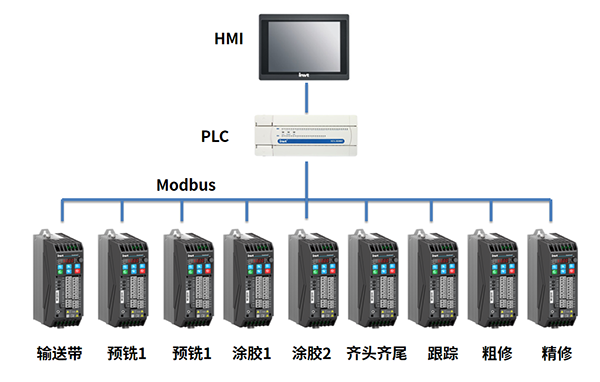

In order to make the debugging of the edge banding machine more efficient and the edge banding effect more beautiful, INVT has launched a high-precision and high-speed motion control solution: HMI+PLC+GD27 inverter to help customers achieve fully automatic and flexible production, promote the continuous optimization and upgrading of the woodworking industry, and achieve lean production.

Significant advantages to accomplish efficient operation and maintenance

* Heavy load design, 150% load for 1min

* Book-like design, space-saving

* Optional rail mounting, easy disassembly and installation

* Optional face cover, beautiful and tidy

* Fast and accurate speed regulation, improve edge sealing quality and reduce energy consumption

Automation solutions for lean manufacturing

* Fully automated solution: based on the existing machinery and equipment throughout the responsibility for the program design, to achieve fully automated edge banding machine program, saving manpower and material resources.

* Process accuracy: the way of recording the real-time position of boards eliminates the sensors of flush, tail and tracking, and controls the error within 0.5mm.

* Working speed: stable edge sealing effect, 200% efficiency improvement, realizing large quantity edge sealing

* Simple operation: touch screen interface design is simple, fine-tuning parameters are around 5, reducing the cost of test plate.

By providing stable speed output, strong communication performance and fast output frequency, INVT solves the problems of traditional edge banding machines, creates tailor-made "high definition" intelligent production line solutions for customers, and strives to promote the upgrading of the woodworking industry.

At present, the woodworking industry has entered a new period of development, and INVT will continue to push forward and provide various system solutions from logs to finished furniture for the woodworking industry, to effectively help customers enhance market competitiveness.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.